Your loft insulation should be at least 270mm thick to meet current UK building regulations and achieve the recommended U-value of 0.16 W/m²K. You’ll need different thicknesses based on material choice: mineral wool requires 270mm, cellulose needs 220-250mm, rock wool performs at 250mm, and PIR boards need only 120-150mm. Your investment can reduce heat loss by 25% and save £115-£215 annually, depending on your house type. Understanding the full scope of options will maximize your insulation’s effectiveness.

Key Takeaways

- Current UK building regulations recommend 270mm thickness for mineral wool insulation to achieve the required U-value of 0.16 W/m²K.

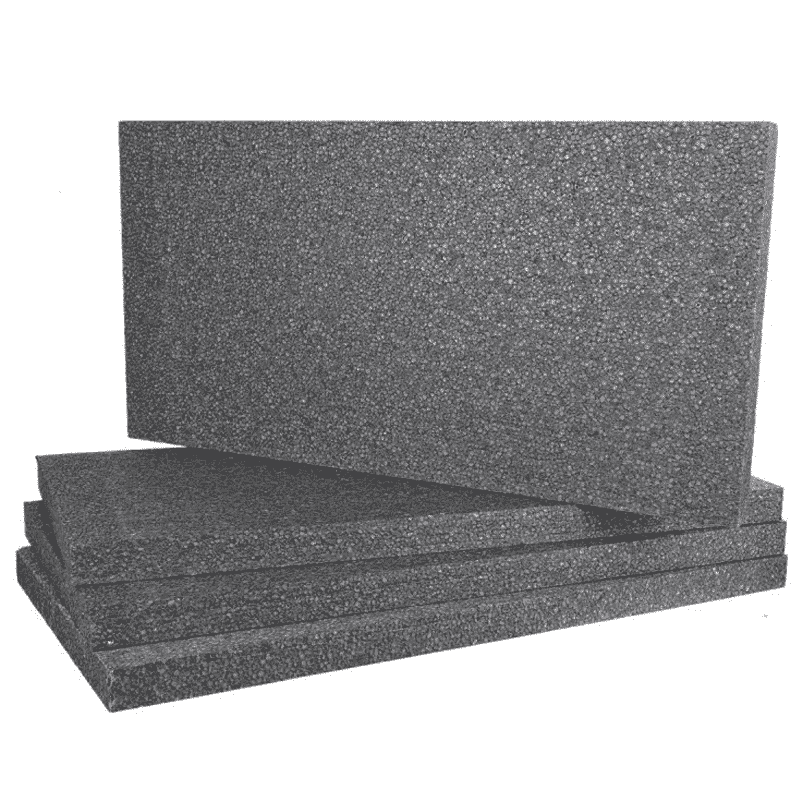

- PIR boards can achieve equivalent insulation performance with reduced thickness of 120-150mm due to superior thermal properties.

- Future climate predictions suggest maintaining or exceeding the 270mm standard to combat temperature fluctuations and rising energy costs.

- Professional installation ensures proper depth and continuous coverage, preventing thermal bridging and maximizing energy efficiency.

- Insulation thickness below 100mm requires complete replacement to meet modern standards and achieve optimal energy savings.

Current UK Standards for Loft Insulation

When considering loft insulation in the UK, you’ll need to comply with Part L of the building regulations, which mandates a recommended thickness of 270mm to achieve a U-value of 0.16 W/m²K.

UK building regulations Part L specifies 270mm loft insulation thickness to meet the required U-value of 0.16 W/m²K.

Your choice of insulation material will affect the required thickness to meet these standards. While mineral wool is commonly used, you might opt for PIR boards or recycled polyester, each offering different thermal properties. Professional installation ensures continuous insulation to prevent thermal bridging and maximize efficiency.

These materials help you achieve ideal energy efficiency while potentially saving up to £35 annually on your heating costs.

Alternative materials like rigid foam boards can achieve the same insulation standards with only 150mm thickness.

As a homeowner committed to energy efficiency, you’ll want to guarantee your loft insulation meets these current standards.

Whether you’re installing new insulation or topping up existing layers, maintaining the recommended thickness is essential for maximizing thermal performance and reducing heat loss through your roof space.

Measuring Your Existing Insulation

Before adding new insulation to meet current standards, you’ll need to accurately assess your existing coverage. Using a tape measure or ruler, take measurements at multiple points across your loft, as insulation depth often varies.

Remember to record these measurements and photograph the areas for documentation. Starting at the eaves and joists, you should carefully inspect for any air leaks that could compromise efficiency.

When conducting your insulation assessment, check for compressed or damaged sections that might require replacement. You’ll want to measure at the lowest points to guarantee minimum coverage throughout.

If your existing insulation is less than 100mm thick or shows signs of moisture damage, you’ll need to plan for a complete replacement. Your goal should be to achieve the recommended 270mm thickness for optimal insulation performance.

For safety and accuracy during measurement techniques, use proper safety equipment like gloves and a mask.

It’s also wise to work with a partner when accessing loft spaces and guarantee proper lighting with a flashlight.

Climate Impact on Insulation Requirements

As global climate patterns become increasingly volatile, the requirements for loft insulation thickness must adapt to maintain ideal home efficiency.

Climate variability impacts mean you’ll need to take into account both extreme cold and heat when determining your insulation needs, particularly as weather patterns continue to shift.

Adapting insulation strategies must consider both temperature extremes, as shifting weather patterns redefine what constitutes effective home protection.

In regions experiencing more severe temperature fluctuations, you’ll want to guarantee your insulation thickness meets or exceeds the recommended 270mm standard.

Fibreglass roll insulation offers a cost-effective solution for meeting thickness requirements while maintaining excellent thermal performance.

Insulation thickness adaptation isn’t just about meeting current needs – it’s about future-proofing your home against changing climate conditions.

You’re joining a community of homeowners who understand that proper insulation is vital for both environmental responsibility and personal comfort.

Eco loft insulation effectively contributes to meeting stricter UK energy efficiency standards while ensuring optimal thermal performance.

Modern materials and innovative technologies now allow you to achieve the best thermal resistance while maintaining adequate ventilation and moisture control.

Material Options and Their Ideal Thickness

Several key insulation materials dominate the loft insulation market, each with specific thickness requirements for peak performance. You’ll find mineral wool benefits include excellent thermal resistance at 270mm thickness, while cellulose efficiency peaks between 220-250mm. Rock wool advantages shine through at 250mm, offering robust insulation with slightly reduced thickness requirements. Proper installation that is tight without gaps ensures optimal thermal performance of any chosen material. Spray foam installations provide exceptional air sealing capabilities but require professional expertise to achieve proper thickness.

| Material Type | Ideal Thickness | U-value Enhancement |

|---|---|---|

| Mineral Wool | 270mm | High performance |

| Cellulose | 220-250mm | Variable density |

| Glass Wool | 270mm | Cost-effective |

| Rock Wool | 250mm | Fire resistant |

| PIR Board | 120-150mm | Space-saving |

For maximum thermal performance factors, you can implement insulation layering techniques. PIR board applications require only 120-150mm thickness due to superior insulating properties, making them ideal for spaces where depth is limited. Glass wool properties mirror mineral wool’s requirements, maintaining effectiveness at 270mm thickness.

Cost Vs Performance Analysis

While homeowners often focus on initial costs, the performance benefits of 270mm loft insulation justify the £290 average investment for a typical terraced house. Maintaining proper insulation depth of 27cm is crucial for meeting government guidelines and maximizing energy efficiency. With spray foam insulation costing up to £37 per square metre, it represents the premium end of available materials.

You’ll find that different insulation types deliver varying performance metrics, affecting both your initial investment and long-term savings.

- Your energy bills can drop considerably, as proper insulation prevents up to 25% of heat loss through the loft.

- You’ll achieve the recommended U-value of 0.16 W/m²K with 270mm thickness, meeting current building regulations.

- Professional installation guarantees ideal performance, though it adds to upfront costs.

- Government schemes like ECO can offset your initial investment through grants and subsidies.

- Your choice of material impacts cost-effectiveness – mineral wool offers an excellent balance between price and thermal efficiency.

Consider these factors alongside your budget to make an informed decision that’ll benefit your home’s energy efficiency and comfort.

Energy Savings and ROI Calculations

Understanding your potential energy savings requires careful analysis of the return on investment (ROI) calculations. When you invest in proper loft insulation, you’ll join thousands of homeowners experiencing significant energy efficiency benefits, with heating bill reductions of up to 25%. Materials like quilt insulation costs typically start around £10 per square meter.

| House Type | Initial Cost | Annual Savings |

|---|---|---|

| Detached | £395 | £215 |

| Semi-detached | £300 | £130 |

| Terraced | £285 | £115 |

Your insulation benefits will vary based on your property type, with payback periods ranging from 12 to 48 months. By increasing your insulation thickness from 5cm to 27cm, you’ll save approximately £35 annually on heating costs. For most homeowners, the investment delivers substantial returns through consistent temperature control and reduced energy consumption, making it a smart financial decision for your home’s future.

Professional Vs DIY Installation Guidelines

Before starting a loft insulation project, you’ll need to decide between professional installation and DIY approaches, as each option presents distinct advantages and compliance requirements.

Your choice will impact both installation techniques and safety measures, ultimately affecting your insulation’s performance and compliance with regulations.

Selecting the right installation approach determines not just the quality of your insulation but also your adherence to building codes.

- Professional installers offer certified expertise, warranties, and access to government grants like ECO4.

- DIY installation can save money but requires proper protective equipment and thorough knowledge of ventilation requirements.

- Complex loft spaces or difficult access points typically warrant professional installation.

- You’ll need specific tools and materials for DIY, including rollers, cutters, and appropriate storage space.

- Professional installation guarantees compliance with U-value standards (0.11 W/m²K for new builds, 0.16 W/m²K for existing homes).

The decision ultimately depends on your technical skills, time availability, and loft complexity.

Properties with minimal loft insulation of less than 100mm thickness automatically qualify for free professional installation through government schemes.

Common Installation Mistakes to Avoid

Whether you choose professional installation or DIY, recognizing common installation mistakes can prevent costly errors and performance issues in your loft insulation project.

You’ll need to avoid several critical installation errors that can compromise your insulation’s effectiveness. Don’t skip accurate measurements of your loft area and insulation thickness, as these directly impact thermal performance.

Watch for insulation gaps and uneven spacing, which create cold spots and reduce efficiency. You must guarantee proper ventilation while sealing air leaks to prevent condensation and mold issues.

For your safety and compliance, always wear protective gear when handling insulation materials, and verify your roof’s structural capacity before installation.

Many homeowners overlook building regulations and fire safety codes – don’t make this mistake.

Remember to maintain a 25mm ventilation gap at the eaves to ensure proper airflow throughout your loft space.

Future-Proofing Your Home’s Insulation

As climate patterns continue to shift and energy costs rise, future-proofing your home’s insulation requires strategic planning beyond current building standards.

Today’s insulation advancements offer innovative solutions that’ll serve you well into the coming decades while supporting sustainable materials and practices.

Modern insulation technology delivers lasting performance through eco-friendly materials, preparing homes for a sustainable and energy-efficient future.

- Smart EIFS technology integration lets you monitor wall conditions in real-time, preventing costly moisture damage.

- Bio-based and recycled sustainable materials provide excellent R-values while reducing your carbon footprint.

- Advanced mineral wool and rigid foam boards deliver superior fire resistance and soundproofing capabilities.

- Cellulose insulation made from recycled materials offers both environmental benefits and effective temperature control.

- Modern drainage systems incorporated into insulation prevent moisture buildup, extending your installation’s lifespan.

Products like natural fiber insulation from recycled materials now offer excellent thermal efficiency while ensuring eco-friendly performance without harmful chemicals.

Frequently Asked Questions

Can I Install New Insulation Directly Over Existing Older Insulation?

You can layer new insulation over existing material if you’ve confirmed insulation compatibility and proper condition. Just guarantee you’re using correct installation techniques and maintaining adequate ventilation to prevent moisture-related issues in your loft.

How Often Should Loft Insulation Be Replaced or Topped Up?

Want to maximize your insulation lifespan? You’ll need to replace fiberglass every 7-10 years, while mineral wool can last 30-80 years. Regular insulation maintenance includes topping up every 10-15 years for peak performance.

Will Thick Insulation Affect the Ventilation in My Loft Space?

Yes, thick insulation can affect airflow, but you’ll maintain proper ventilation balance by keeping a 50mm gap at the eaves. This guarantees you’ll get insulation benefits while preventing moisture issues in your loft space.

Does Storing Items in the Loft Compress and Reduce Insulation Effectiveness?

Just like your loft organization plans, your insulation material’s performance is at stake. When you store items directly on insulation, you’ll compress it, reducing its effectiveness by disrupting essential air pockets that trap heat.

Can Rodents or Pests Damage Loft Insulation Over Time?

Yes, rodents can severely damage your loft insulation by burrowing and nesting. You’ll need regular insulation maintenance and pest prevention measures, including sealing entry points and professional inspections, to protect your insulation’s effectiveness.

Conclusion

By upgrading your loft insulation to 270mm-300mm thickness in 2025, you’ll achieve superior thermal efficiency while meeting advancing building regulations. While traditional glass wool requires greater depth, modern aerogel solutions can deliver equivalent performance at 40mm. Your choice between maximum energy savings (£250-£300 annually) and space preservation will determine the ideal thickness, balancing current standards with future-proof specifications that anticipate stricter environmental requirements.

References

- https://ecowiseinstallations.co.uk/uk-loft-insulation-grants/what-is-the-best-thickness-for-loft-insulation/

- https://koalainsulation.com/orlando-central/blog/how-thick-should-my-insulation-be-for-maximum-efficiency

- https://highloft.co.uk/blogs/blog-posts/the-uk-government-s-guidance-on-loft-insulation-what-you-need-to-know

- https://koalainsulation.com/f/orlando-central/blog-detail/how-thick-should-my-insulation-be-for-maximum-efficiency

- https://www.greenmatch.co.uk/insulation/thickness

- https://www.greenmatch.co.uk/insulation/rules-regulations/roof

- https://www.yorkshireloftladders.co.uk/how-thick-should-loft-insulation-be/

- https://www.buildingmaterials.co.uk/info-hub/insulation/how-thick-should-loft-insulation-be

- https://www.theloftboys.co.uk/lofts/loft-insulation/

- https://www.roofingmegastore.co.uk/blog/how-thick-should-loft-insulation-be.html